About

Film Thickness Gauges

Film Thickness Measurement: Why Accuracy Matters

Film thickness measurement plays a vital role in industries such as packaging, medical devices, food, electronics, and textiles. The thickness of a film directly impacts its strength, flexibility, barrier properties, and overall quality. Too thin, and the film may tear or fail to protect contents; too thick, and production costs rise unnecessarily. For manufacturers, achieving the right balance is not only about performance and safety but also about regulatory compliance and customer satisfaction.

Today, companies rely on advanced film thickness gauges and measurement equipment to ensure their products meet stringent industry standards. Precision in measurement helps reduce waste, optimize materials, and maintain consistency across production batches.

Film Thickness Gauge

Film Thickness Gauge and Its Role in Quality Control

A film thickness gauge is a specialized instrument designed to evaluate the thickness of plastic, BOPP, or other thin films with high accuracy. Unlike manual methods, which may produce inconsistent results, modern gauges provide repeatable, reliable data.

In quality control laboratories, a film thickness gauge is used for:

- Verifying material compliance with international standards.

- Monitoring uniformity across production.

- Detecting weak points or defects in the film.

- Controlling costs by minimizing excess material usage.

By integrating these instruments, manufacturers ensure that products perform as intended while also maintaining production efficiency.

Film Thickness Gauge

Thin Film Thickness Measurement Instruments

The term thin film thickness measurement instruments refers to tools capable of measuring ultra-thin layers—often in the micrometer range. These instruments are vital for sectors that demand extreme precision, such as electronics, medical packaging, and high-performance films.

The main benefits include:

- High resolution and sensitivity, allowing detection of even minute variations.

- Non-destructive testing methods, which preserve sample integrity.

- Statistical analysis capabilities, helping teams assess maximum, minimum, average, and standard deviations.

When accuracy is critical, thin film thickness measurement instruments become an essential part of any production or R&D workflow.

Thickness Measurement

Plastic Film Thickness Measurement Applications

Plastic film thickness measurement ensures that products meet both functional and regulatory requirements. Industries that rely on consistent film quality include:

01

Food packaging

Uniform thickness prevents contamination and ensures barrier protection.

02

Medical packaging

Reliable film prevents leaks and maintains sterility.

03

Pharmaceuticals

Blister packs and sachets require consistent thickness for stability and protection.

04

Textiles and membranes

Ensures durability and expected performance.

In these industries, precision measurement safeguards both consumer safety and brand reputation.

Film Thickness Gauge

Film Thickness Measurement Equipment for Production Efficiency

Using advanced film thickness measurement equipment allows manufacturers to reduce waste and optimize material usage. Modern devices are equipped with:

- PLC-controlled systems with user-friendly touch screens.

- Automatic presser foot lifting to simplify testing.

- Real-time statistical displays.

- Data storage and connectivity options for integration with quality management systems.

These features ensure that every batch of film meets exact specifications, reducing the risk of recalls or customer complaints.

Film Thickness Gauge

Plastic Film Thickness Gauge: Choosing the Right Instrument

BOPP (biaxially oriented polypropylene) film thickness measurement is one of the most common applications in the packaging industry. BOPP films are used in food wrapping, adhesive tapes, and labels, requiring high clarity, strength, and uniformity.

Inconsistent thickness can lead to poor sealing, compromised product protection, or increased material costs. Reliable testing equipment ensures that BOPP films perform as expected in demanding packaging applications.

Selecting a plastic film thickness gauge requires considering factors such as:

- Range and resolution: Does the gauge meet the film thickness you need to test?

- Sample type: Will it measure plastic, paper, textiles, or composite films?

- Ease of operation: Can operators perform tests quickly and consistently?

- Data handling: Does the system store results and support software integration?

The right plastic film thickness gauge ensures dependable performance in both research labs and large-scale production facilities.

Film Thickness Gauge

BOPP Film Thickness Measurement: A Specialized Need

Film Thickness Gauge

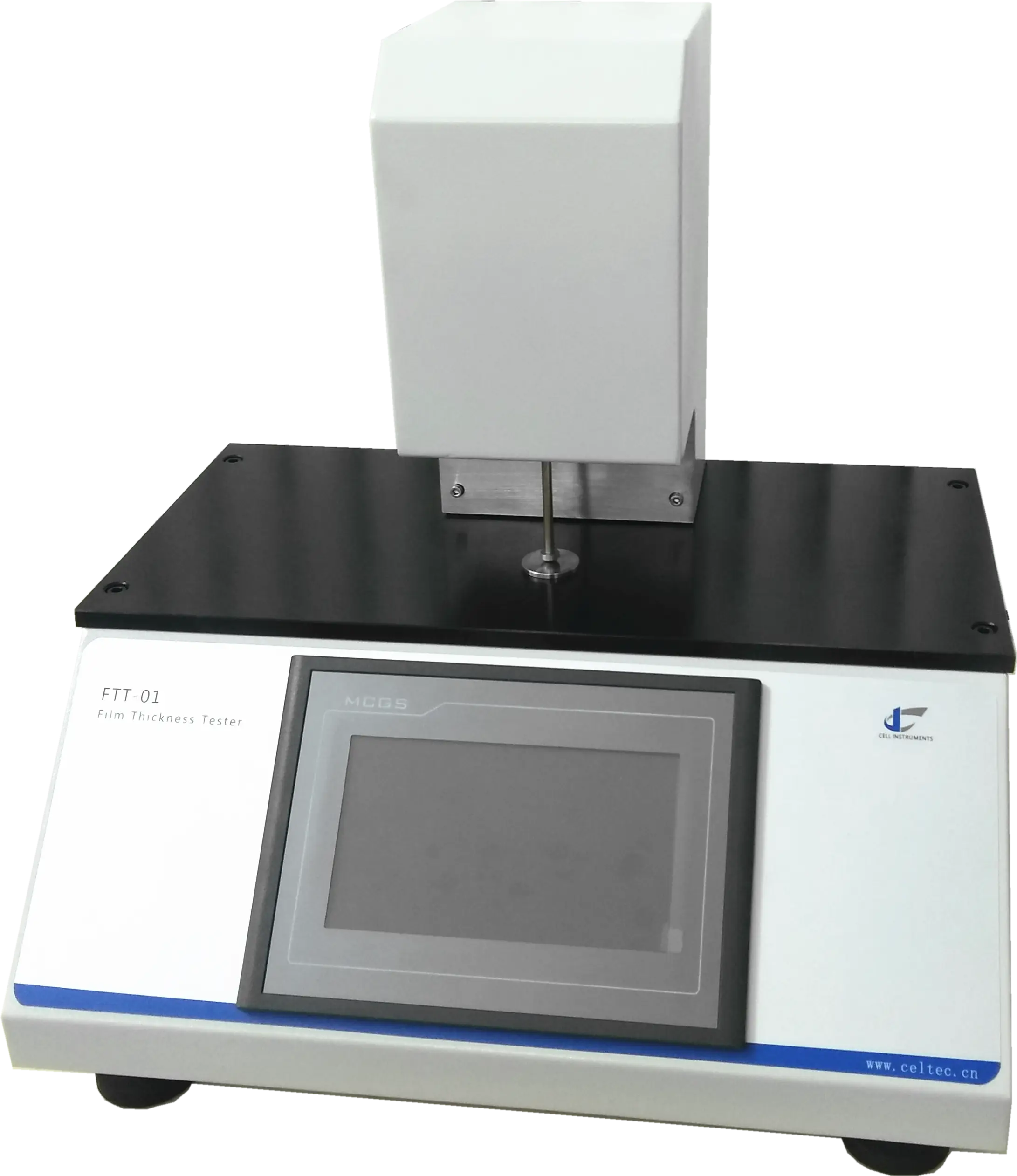

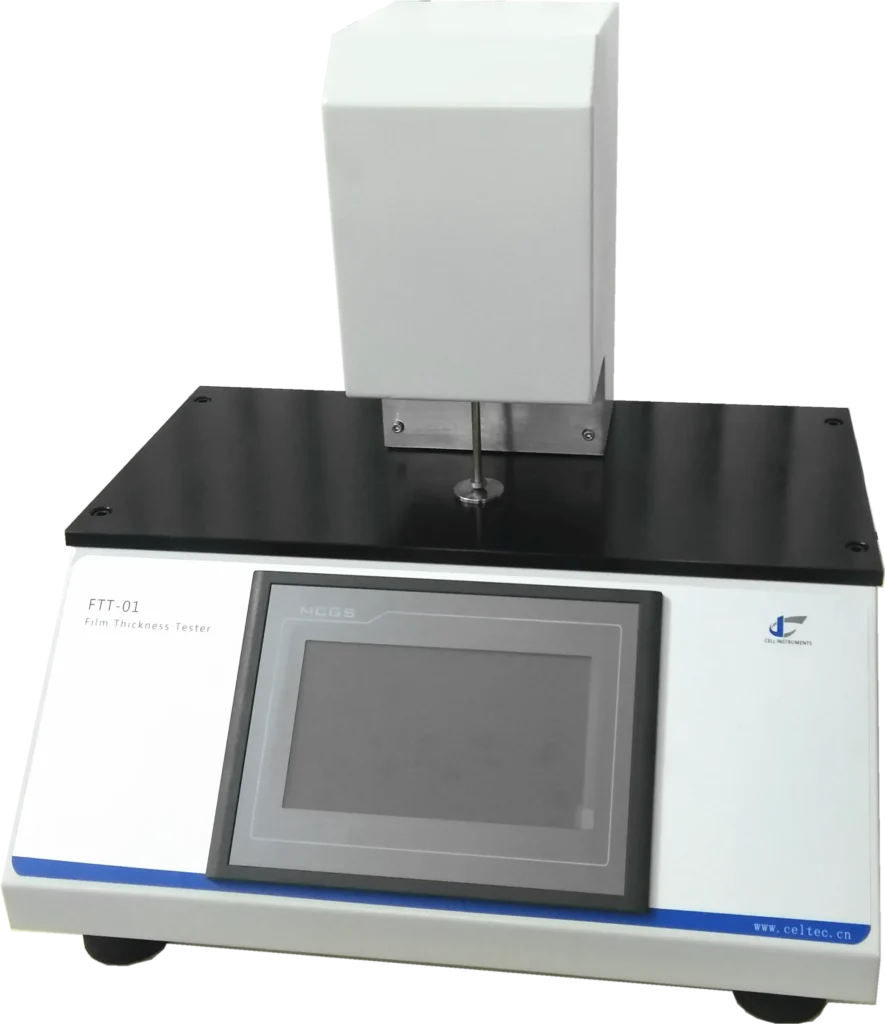

Cell Instruments FTT-01 Film Thickness Tester

01

FTT-01 Thickness Tester

For businesses seeking high-precision, reliable film thickness measurement, Cell Instruments offers the FTT-01 Thickness Tester. This equipment is designed for:

- Measuring plastic films, paper, foils, textiles, and membranes.

- Providing 0.1 μm resolution for precise measurement.

- Offering statistical analysis, including max, min, average, and standard deviation.

- Supporting both manual and automatic feeding options.

- Delivering data storage and optional software connectivity for process integration.

By implementing the FTT-01, manufacturers can enhance quality control, improve production efficiency, and meet international standards.

"Choosing Cell Instruments means working with a company that specializes in innovative material testing solutions. With years of expertise, we serve industries ranging from packaging and food to medical, pharmaceuticals, textiles, and electronics."

– Cell Instruments

Frequently Asked Questions about Film Thickness Gauges & Equipment

1. Why is film thickness measurement important in manufacturing?

Film thickness measurement ensures that materials like plastic, BOPP, or medical films meet functional, regulatory, and cost requirements. Consistent thickness prevents defects such as tearing, poor sealing, or barrier failure, while also reducing unnecessary material use.

2. What instruments are used for plastic film thickness measurement?

Specialized film thickness gauges and measurement equipment are commonly used. For high-precision testing, instruments like the Cell Instruments FTT-01 Thickness Tester provide reliable results with micrometer-level resolution, ensuring compliance with international standards.

3. How does a film thickness gauge work?

Most gauges operate by placing a weighted presser foot onto the film sample and measuring the displacement between the presser foot and the base. This gives an accurate reading of the film’s thickness. Advanced models provide real-time statistical data such as minimum, maximum, average, and standard deviation.

4. What industries require thin film thickness measurement?

Industries including packaging, food, pharmaceuticals, medical devices, textiles, and electronics rely on thin film thickness measurement. For example, in BOPP film packaging, uniform thickness ensures sealing strength and product protection, while in medical packaging, it safeguards sterility and safety.

5. Why choose Cell Instruments for film thickness measurement equipment?

Cell Instruments offers professional, high-precision solutions backed by expertise in packaging, medical, and industrial material testing. Our FTT-01 Thickness Tester combines accuracy, automation options, and data integration—making it ideal for both research labs and high-volume production lines.

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985